One of the best things about mechanical keyboards is the fact that they are customizable. And the easiest way to express your personality on your keyboard is to change the keycaps. However, you must know that there are different types of keycaps.

ABS keycaps are less durable than PBT keycaps. However, colors are more accurate in ABS keycaps which is why more high-end brands use them. PBT keycaps, on the other hand, are more durable but generally have less vibrant colors. They are also more susceptible to issues such as spacebar warping.

In this article, we will further discuss the difference between PBT and ABS keycaps. We will go through their advantages and disadvantages. And by the end of this article, you should be able to decide which keycap type you should purchase for your mechanical keyboard.

What are Keycaps?

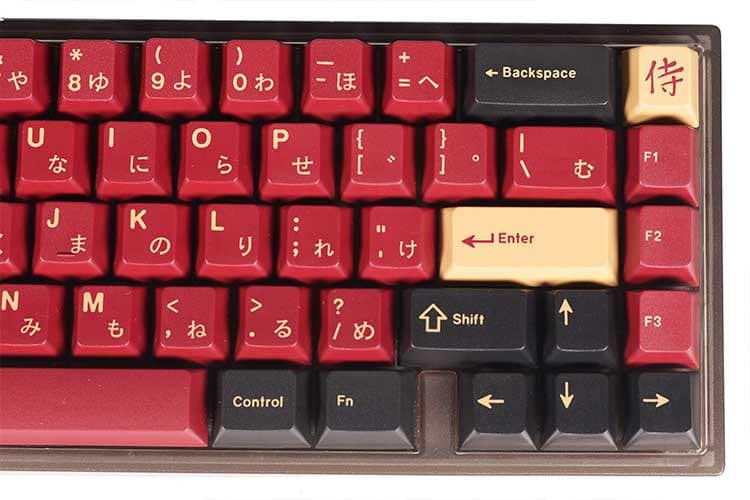

Keycaps are basically the face of a keyboard. They are the first thing that you look at when you check one up. And they can come in different shapes and sizes.

But none of the pretty colors or the cool figures printed on them really matter if they are not made out of good durable plastic, right? When it comes to the types of plastics used, two are heavily known around the keyboard world: ABS and PBT.

What are ABS Keycaps?

ABS is short for Acrylonitrile Butadiene Styrene. This plastic is the most used out of the two due to it being the cheapest. The manufacturing of keycaps with this type of plastic is easy due to its low melting point.

This plastic makes keycaps that come with most of the normal membrane keyboards you see everywhere. But can easily be found for mechanical keyboards.

When it comes to durability, this plastic falls behind. It’s the type of plastic that, after long heavy use, loses its “new” texture and becomes shiny and dirty looking.

Whether the legends (the signs, letters, symbols on the key) stay over time fully depends on the process used to place them on the keycaps or even the process used to make the keycap itself. This process is called printing. And for the ABS Keycaps, there are two types of “printing” the legends on keycaps.

Double Shot:

This process is for placing legends on the keycaps and is a way to manufacture keycaps themselves. This involves having two different molds for each different key in which the molten ABS is poured. After they set and are hard, the two pieces that correspond to one keycap are put together.

The outer layer is the visible part of the keycap, which you press on your keyboard, with a hollow space where the legend is. The inner layer can only be seen as the legend on the key. The rest of the plastic is on the inside.

This process of making keycaps makes this not-so-durable plastic better because now there are two layers in the whole thing. You will not be able to escape the shiny look that will come after a while of heavily using them.

But you will not lose the legends on the keys since they are not printed on top of the keys. Because the legend is a whole piece of plastic, Another good side to this is the opportunity to have good-looking color combinations between the outer and inner layers.

Pad Printing:

This process is for adding legends on top of the already made keycaps. It is the most common process of placing legends on top of keycaps because of its low cost. All this consists of is placing the keycaps down and having a pad with ink pushed against them, printing the legend on them.

The good side of this method is the room for creativity, allowing you to have any color printed on your keys. The bad side is that these are just a layer of ink on top, which can wear out and disappear over time.

What are PBT Keycaps?

PBT is short for Polybutylene Terephthalate. This type of plastic is widely known in the mechanical keyboard world. For those who enjoy customizing their keys, this is the type you will find yourself ordering the most.

The quality of this type of plastic is heavier than that of the ABS. This brings more durability to the life of each keycap, with the bonus of not having them turn greasy and shiny over excessive use.

Their texture is rather grainy or dry compared to the texture on ABS keycaps and is helpful over time. This type of plastic has a high melting point allowing for a process of printing called Dye Sublimation.

Dye Sublimation:

This process is quite interesting and expensive since it requires manual labor a lot of the time it is done. In addition, this process uses PBT because of its high melting point, meaning it takes more heat to melt a key. Finally, a key is all done and prepared, waiting for its legend to be placed on top. But unlike the other two procedures, this one requires a different method.

This involves having the legend printed on a special piece of paper being pushed onto the key and set to high heat. This heat over time will heat the key to open its “pores,” allowing the evaporating ink to travel and be trapped in them.

The traveled ink only has room to go into the keycap to keep the shape of the corresponding legend. This way of printing makes the legends last long in the keycap but could wear out if heavy use is applied over time. This process is used to bring custom keys and styles to keyboards and elevate the levels of creativity.

Pros and Cons

ABS

Pros:

- Cheaper than PBT.

- Easier to find.

- If used in Double Shots, the legend lasts forever.

- Good for creative customizations

- Can come in every color you may think of.

- Smooth to the touch.

- Known to be quieter than PBT.

Cons:

- Not the most durable type of plastic.

- Gets shiny and greasy over time giving a dirty look as it ages.

- If legend is printed on top, it will wear out and fade over time.

- Lower quality plastic.

PBT

Pros:

- Higher quality plastic.

- Much more durable than the normal ABS.

- Maintains its matte texture over time.

- A wide variety of colors and prints on the keys which elevate the levels of creativity and customization.

- Gives grainy textures that some find satisfying.

Cons:

- More expensive than ABS.

- Louder than ABS keys.

- Ink may fade away over a long time.

Which is Better?

It all comes down to your budget and preferences. Do you want something cheap and functional? Take the ABS Keycaps. Looking for a long-term investment for your keyboard? Go with PBT Keycaps. Want a set of Double Shot keycaps? Go for ABS Keycaps. Maybe a set of aesthetically looking keys? Go for Dye Sublimated PBT Keycaps!

Quick Recap of Everything.

- Keycaps are the face of your keyboard. They are the plastic buttons that you press. So not only do they have to look pretty, but they also are strong and durable.

ABS Keycaps

- Are the most commonly found keycaps there are. The plastic is cheaper, which is good if you are on a budget. But the durability suffers, and so does the feel of the key over time. The keys will wear out and become shiny after a long time of using them. There are two common types of printing for these keys:

- Double Shots: These are a well-known type of ABS keycaps. They are two layers of plastic put together. One shows outside but has the legend space hollow. The inner piece fits like a puzzle entering the hollow part of the legend. This allows for cool color combinations. Also, the legend will never fade away because it is not printed. It is a piece of plastic itself.

- Pad Printing: These are the standard cheap keycaps you find almost everywhere. The legends are basically printed onto the keycaps. The good side is you can find the colors you want. The bad side is the ink of the legends will most likely wear out and fade away with time.

PBT Keycaps

- Mechanical keyboards mostly use them. These are more expensive and durable due to their higher quality. In addition, they have a grainy matte texture that most find satisfying, which will not become shiny and greasy over time. There is one very well known printing method for this type of plastic:

- Dye Sublimation: Also known as dye-sub keycaps. This process involves pressing a special paper with the legend on it onto the keycap at high temperatures. The high temperature will open up pores on the keycap allowing the ink to evaporate and incorporate into the keycap. This type of printing allows for some amazing artful key sets that are very aesthetically pleasing. However, if these types of keys are very heavy, the ink will slowly fade over time.

There are plenty of ways you can go when it comes to keyboards, and it does not stop when it comes to keycaps. With all this information that you just absorbed, you should be completely ready to go into a store and pick the type of keys you know you want. Good luck making your next wise investment!

The KBE team is dedicated to sharing our knowledge and creating useful resources about computer keyboards. This article was written as a team collaboration, combining our knowledge and years of experience using, building and modding keyboards. Meet the team here.