One misconception in the custom keyboard community is that soldered PCBs are essential in a good keyboard build. While this was the case for many years, hot-swap PCBs have started to become more popular in the custom keyboard scene. Even high-end keyboard manufacturers are now offering hot-swap PCB options with their keyboards.

With the abundance of hot-swap PCBs in the market, they are becoming the norm for keyboard builds at any price point. They help speed up the whole assembly process without affecting the typing sound and feel of the keyboard. In terms of overall value, you can’t go wrong with hot-swap builds.

Of course, hot-swap keyboards will have some limitations compared to soldered keyboards, including layer options and durability. However, enthusiasts believe that these minor quirks do not take away the many benefits of hot-swap keyboards.

In this article, we will further talk about the benefits of hot-swap custom keyboard builds. And by the end of this article, it should be clear to our readers that it is possible to achieve high-quality custom keyboard builds without soldering.

Why Do High-End Keyboards Have Solder-Only PCBs?

Before we get started with our discussion, let us first talk about why high-end custom keyboards predominantly used hot-swap PCBs in the past. Before the custom keyboard hobby hit the mainstream, most if not all custom keyboards utilized soldered-only PCBs.

Even today, many high-end custom keyboards still exclusively feature a soldered PCB. There are, however, many concrete reasons why this is the case.

The most obvious reason is stability and durability. Since switches are fixed into place in soldered keyboard builds, it is highly unlikely for the switches to pop off when taking off keycaps. Also, the switches will be able to endure a significant amount of abuse since there won’t be any sockets that will be failing.

In addition, soldered PCBs give the user more options in choosing their preferred layout. Users can opt for unorthodox layouts such as split backspace, split Stepped Caps Lock, split space bar, and many more. This kind of customization allows user to truly tailor-fit their keyboards to their needs.

But with that said, hot-swap PCBs in custom keyboards are starting to get better. The demand is also rising, prompting many keyboard manufacturers to include hot-swap PCBs with their keyboards.

Why Hot-Swap PCBs are Becoming the Norm for Custom Keyboard Builds

As we have mentioned earlier, hot-swap PCBs are starting to become the norm despite the many benefits of soldered PCBs for custom keyboards. They aren’t just showing up with budget custom keyboards but also higher-end custom keyboards such as the upcoming Graystudio Space65 V3.

There are various reasons as to why this is the case. Here are some common reasons that the keyboard community has collectively come up with.

Experimentation with Different Keyboard Switches

Keyboard switches are arguably the component that determines how good a particular keyboard build will be. They play a huge role in shaping the overall sound and feel of a keyboard. Thus, it is important to select the proper switch for your keyboard build.

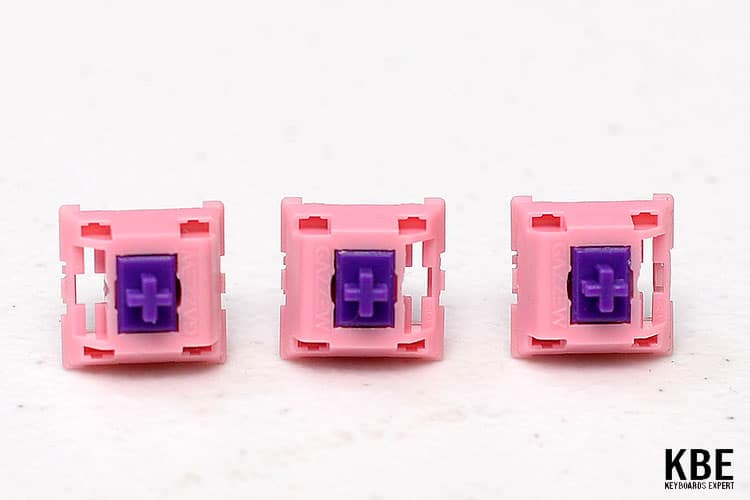

With a hot-swap PCB, users do not need to stick with a single switch type. They can freely experiment with different switches to try out which keyboard switch will produce the best typing feel and typing sound for their keyboards.

This kind of experimentation is incredibly useful, especially with newer custom keyboards with more complex designs. Also, since there are always new switches being released, users can continuously experiment and refine their keyboards until they find the perfect combination that will perfectly satisfy them.

Easier Access to Stabilizers

Aside from the switches, the stabilizers are another integral part of a custom keyboard build. They determine how good the longer keys will feel. The spacebar area is specifically crucial since it will be the most pressed part of the keyboard.

With hot-swap PCBs, users will be able to access the stabilizers without having to desolder the switches. As we will be talking about later, you can easily take the entire keyboard apart for modifications.

Faster Build Time

Another reason why hot-swap PCBs are now preferred is that they allow for a faster build time. Keyboard enthusiasts will no longer need to prepare various equipment and spend time soldering each individual switch. Also, they no longer need to learn and experiment through trial and error if they do not have any basic soldering experience.

Cost-Efficient

In addition to saving time, users will also save costs since they do not need to purchase soldering equipment. Soldering equipment can be very costly, especially for those just starting out.

Easier Keyboard Modification

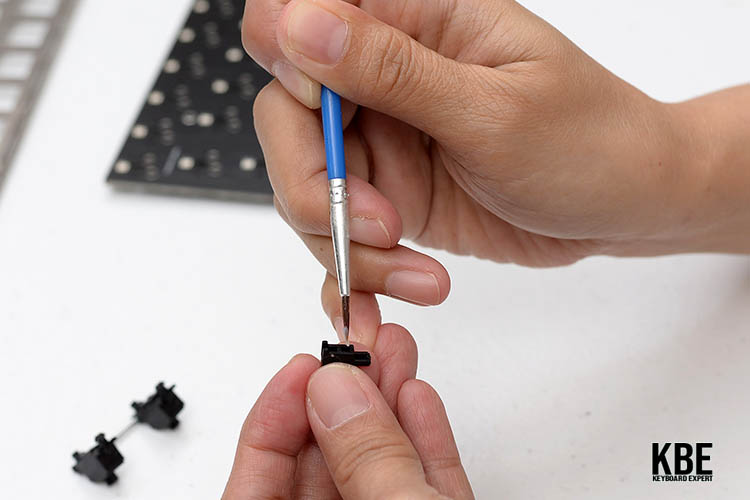

Lastly, with a hot-swap PCB, keyboard modification is a lot easier. The keyboard can be taken apart entirely without the need for specialized tools or equipment. Ease of disassembly is important since it allows users to easily modify and experiment with their keyboard.

Users can try between lubed and unlubed switches, filmed switches, spring swapping, and other types of alternate keyboard switch configurations. They can also easily remove the switches to try out different mods, such as the PE Foam mod.

Of course, these kinds of mods can still be done with soldered keyboard builds. However, it will be significantly harder since you must first desolder each keyboard switch.

Different Layout Support

As a bonus, some hot-swap custom keyboards also feature support for alternate layouts. Some examples include the Meletrix Zoom65 and the Wuque Studio Ikki68 Aurora. Both have been designed to support a wide variety of layouts through the intelligent placement of the hot-swap sockets.

Of course, these two keyboards will have their limitations. Also, the majority of hot-swap keyboards currently do not support different layouts. However, these two show that it is possible and it is expected for other companies to follow this trend.

Can You Build a Good Keyboard With Just a Hot-swap PCB?

Going back to our initial question, yes, it is possible to build a good keyboard without soldering. As we have shown in the previous section, hot-swap PCBs have pretty much taken over the keyboard market and have adapted a lot of the benefits of soldered PCBs.

They make the building process easier, and they are slowly integrating support for multiple layouts. And while most hot-swap PCBs are still not perfect, they are more than good enough for the majority of the keyboard community.

In addition, hot-swap PCBs open up the user to many different modifications, including keyboard switch modifications, stabilizer modifications, PE Foam and Tape Mod, and many more. These all ensure that the user will be able to achieve their desired sound quality and typing feel.

Stephen is the head content creator of Keyboardsexpert. His mechanical keyboard journey began in 2014 when he got his Razer Blackwidow. Since then, he has been fascinated with all things mechanical keyboard-related. He later discovered the custom keyboard hobby and fell in love with the vast customization options. He is currently searching for his endgame and is very excited to share his journey and educate other keyboard enthusiasts.